This research presents a new system for Collective Robotic Construction (CRC) with amorphous materials. Differential Boundary Deposition, a novel additive construction technique, is co-developed with a mobile depositor robot and a design-to-production computational workflow in order to achieve a complete construction system. This system is designed for serial production and can serve as a platform for further research into CRC techniques that have no analogue in traditional construction.

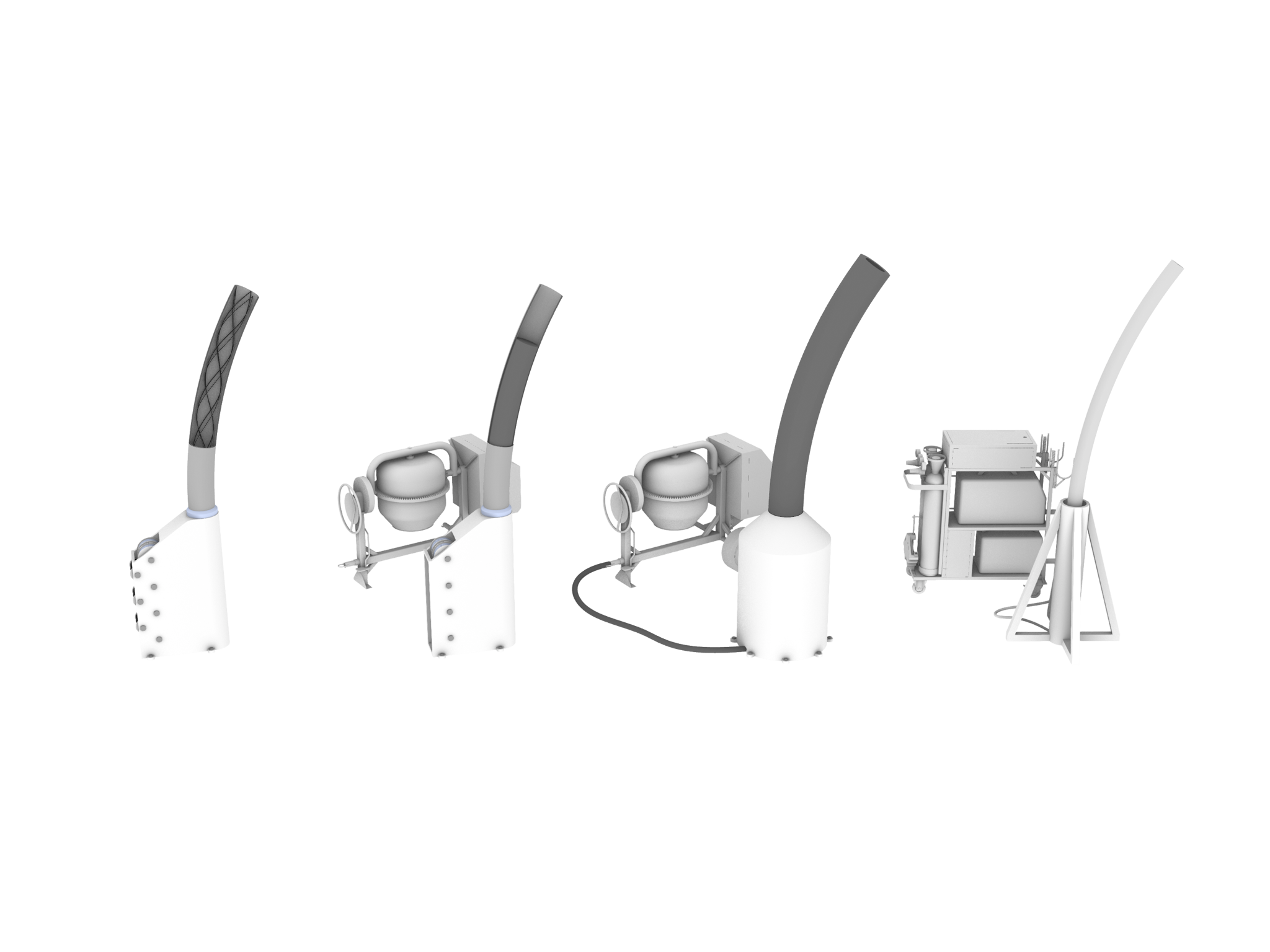

Differential Boundary Deposition is achieved through the continuous addition of a fluid material to a growing structure from within. The deposition head simultaneously adds material around its entire perimeter as it moves forwards through space, resulting in a continuously growing tube structure. In contrast to extrusion or casting, the material does not take its shape by being forced through a die or by filling a formwork. Rather, the combination of self-adhesion, pressure, and contact with the surface of the mobile depositor results in a continuously deposited tube structure. Each mobile depositor robot, including its supply of material and power, is fully contained within the structure that it builds. This allows the tubes constructed by different mobile depositors to interact with each other and fuse. Therefore, a team of mobile depositor robots can collectively build a network of tube structures that could not be built using a different deposition method, or a single robot acting alone.

The proposed CRC system is validated through a series of physical experiments using a prototype mobile depositor, a thermoplastic demonstration material, and an integrated design-to-production computational workflow. This system demonstrates the benefit of developing new material-robot methods for construction by challenging current construction methods in terms of speed, strength, and material efficiency, as well as by opening a new morphological space for architectural design.