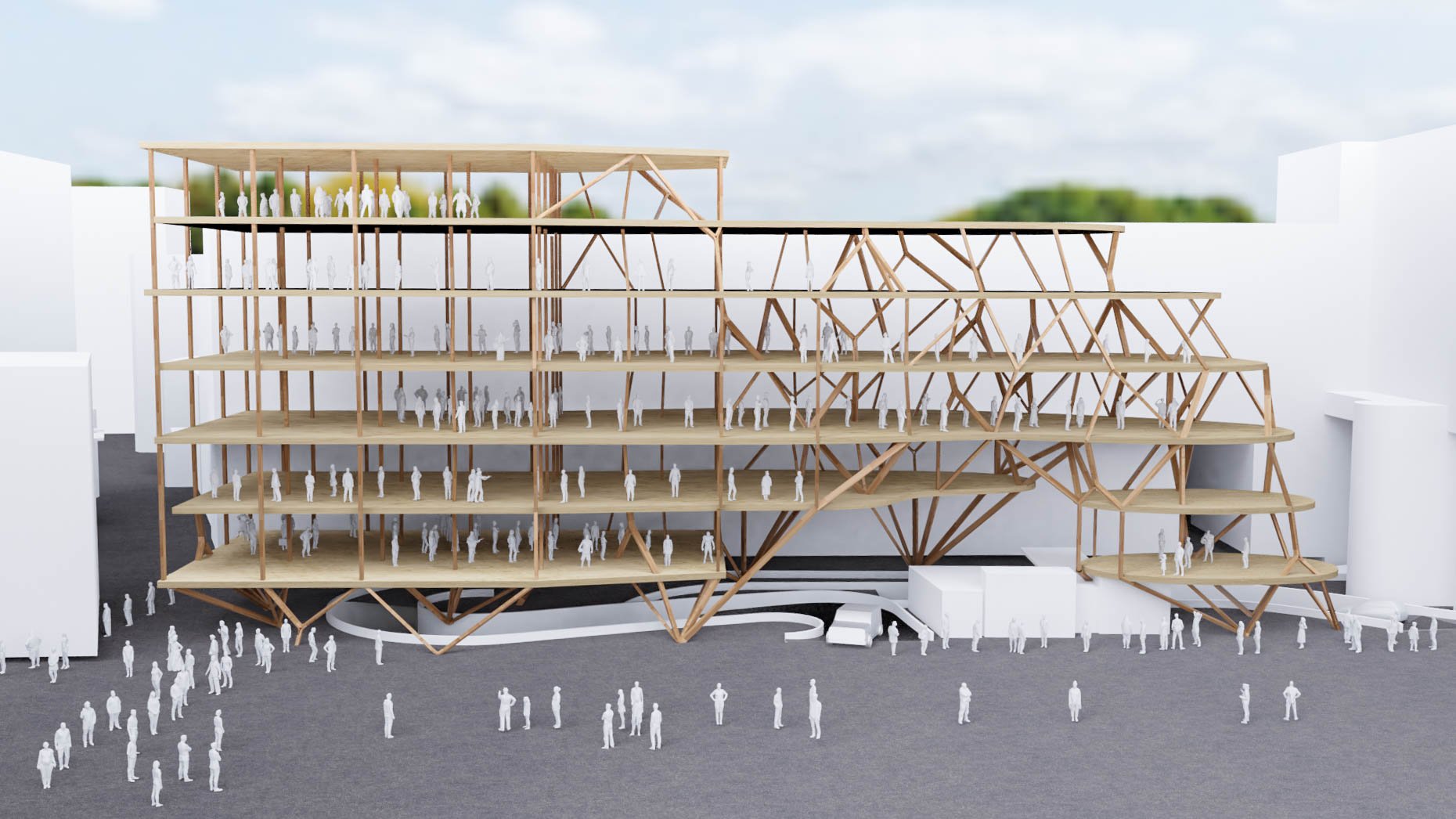

This work explored generative algorithms for the production of non-orthogonal structral skeletons. Together with the investigation of all-timber customized joint fabrication a structural system was proposed that can be produced from sustainable engineered timber with minimal steel hardware.

Generative Timber Skeletons

ITECH Studio Work | 2020-2021

Universität Stuttgart, Germany

Tutors: Luis Orozco | Gregor Neubauer | Hana Svatos-Raznjevik | Anna Krtschil

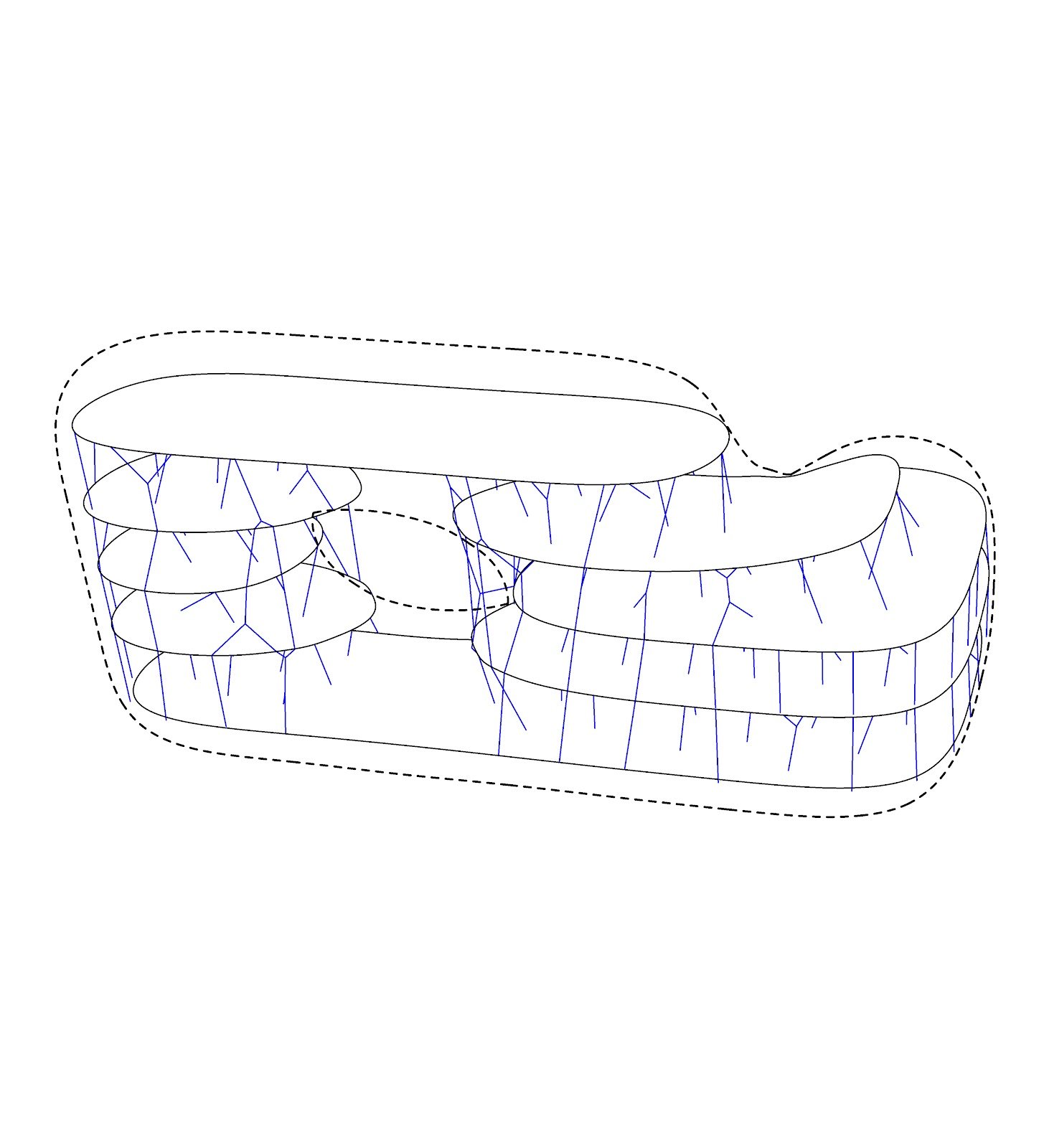

Load conditions and excluded zones are driven by architectural design decisions.

The building volume is considered as a solid object, and a topological optimization algorithm finds optimal force flows and stress concentrations within the volume.

Principal stress vectors go through threshold and noise reduction operations, leaving behind cleaned force paths.

Force paths are translated to structural element centerlines and go through a process of rationalization to produce final design geometry.

Orthogonal design geometries tend to yield regular, grid-like structural skeletons.

Organic design geometries tend to yield irregular, branching structural skeletons.

It is possible to implement gradients and seamless transitions between orthogonal and organic geometry.